Introduction: Why Oil Press Machines Are a Game-Changer

Silicone products are a big deal in industries like healthcare, cars, everyday items, and electronics. Folks love them because they’re strong, bendy, and can take the heat. At CASINDA, we use top-of-the-line oil press machines to turn raw silicone into awesome silicone products. This way, we make sure everything is spot-on, fast, and can grow with demand. It helps us keep our customers around the world happy.

In this blog, we’ll take you through the steps of making silicone products with oil press machines. Whether you’re just starting out or want to make your process better, this guide will show you how to improve quality and get things done faster.

Step 1: Getting the Raw Materials Ready

Picking the Best Silicone

The secret to great silicone products? Start with great materials. At CASINDA, we choose high-quality silicone rubber compounds to make sure our products are solid. We look for materials that handle heat well, stay flexible, and don’t break down with chemicals. Using top materials means our products pass tough industry tests.

Prepping the Silicone

Before we shape the silicone, it needs a bit of prep. We mix it with stuff like curing agents, colors, or fillers, depending on what the product calls for. This makes sure the silicone sets just right when molded. It also gives it the perfect look and feel. At CASINDA, we use high-tech mixing tools to get the silicone ready. Every batch comes out just as good as the last.

Step 2: Shaping with Oil Press Machines

What’s an Oil Press Machine?

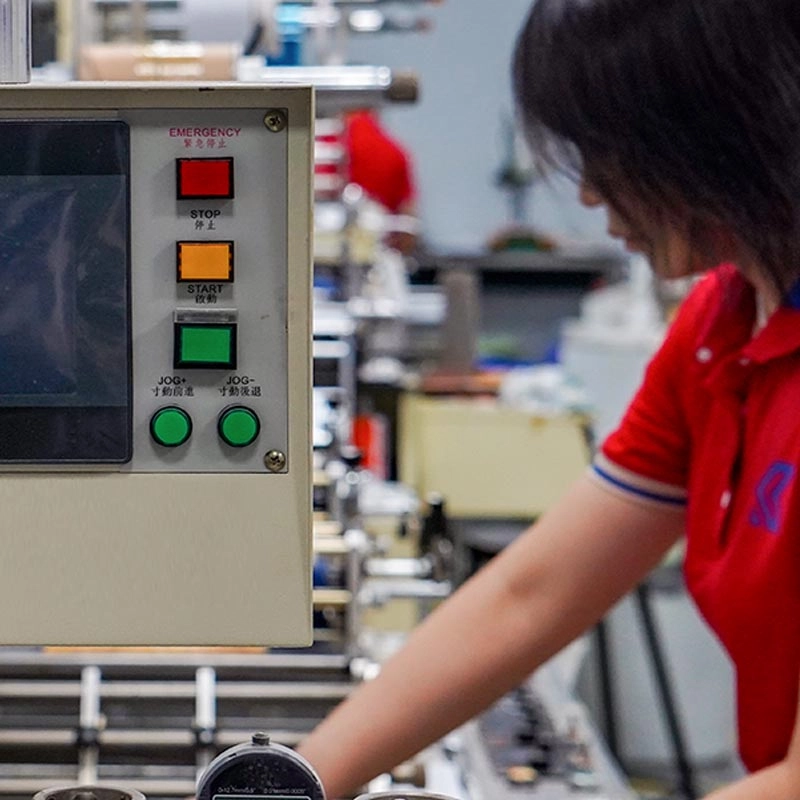

At CASINDA, we use sleek oil press machines to shape silicone into its final form. These machines gently push the silicone into molds to create the shape we need. They’re perfect for silicone because they can handle high heat and pressure. This helps the silicone set properly.

Our machines are packed with the latest tech. They let us fine-tune heat and pressure. That way, we make consistent products, even when we’re churning out tons at once.

Adding Liquid Feeding Systems

To speed things up, we pair our oil press machines with automated liquid feeding systems. These systems pour silicone straight into the molds. No need for extra hands-on work. This makes production faster and keeps things clean. It also ensures the silicone spreads evenly in the mold.

Step 3: Curing and Taking Out of Molds

The Curing Step

After shaping, the silicone gets cured. This hardens it and locks in its final qualities. We heat it to a specific temperature for just the right amount of time. This makes sure it’s the perfect mix of hard, flexible, and chemical-resistant.

At CASINDA, we keep a close watch on curing. This ensures our products hit high standards. We adjust the process for small parts or big ones to match what the product needs.

Getting Products Out of Molds

Once the silicone is cured, we carefully take it out of the mold. This step, called demolding, is super important to keep the product’s shape and quality. At CASINDA, we use clever demolding tricks. We remove products gently to avoid any damage. With smart heat control and neat methods, we keep flaws to a minimum. Our products come out just as expected.

Step 4: Checking Quality and Adding Final Touches

Making Sure Everything’s Perfect

Quality is our top focus at CASINDA. We have careful checks to ensure every product is up to par. Our team looks at size, surface finish, and how well the product works. We also test products to make sure they hold up in real-world use.

We check every batch for the same color, hardness, and flexibility. This keeps our customers thrilled with the quality they get from us.

Finishing Up

Some products need a little extra love after demolding. We might trim off extra bits, smooth out surfaces, or add coatings for strength or style. CASINDA can handle these final steps. We make sure every product is exactly what our customers want.

Step 5: Packing and Shipping

Packing Products Safely

Once products are checked and finished, we pack them with care. At CASINDA, we use custom packaging to keep products safe during shipping. Our packaging makes sure everything arrives in great shape. We’re extra careful with delicate items.

Getting Products to You

Getting products to customers on time is key. CASINDA teams up with trusted shipping partners to deliver quickly and affordably. We work with clients to plan delivery schedules. This ensures every order shows up right when it’s supposed to.

Conclusion: CASINDA’s Commitment to Doing Things Right

At CASINDA, we’re all about making awesome silicone products for all sorts of industries. Our high-tech odm accessory of oil press machine and smart methods deliver strong, reliable results. Whether you need custom parts or big production runs, we’ve got the skills and tools to make it happen.

In today’s fast-paced world, quality and speed matter. That’s why we keep investing in better tech and fresh ideas. At CASINDA, we’re driven by making great products and keeping our customers happy.

FAQ

Q: What kinds of silicone things can I make using oil press machines?

A: Oil press machines are really handy! You can create loads of items. Think medical tubing, car gaskets, kitchen tools, phone cases, and even seals for electronics. Pretty much anything that needs to bend easily, last a long time, or handle heat can be shaped with these machines. You just need the correct mold.

Q: How do I pick the right oil press machine for my silicone work?

A: It really comes down to what you’re making. Check the machine’s pressure and how hot it can get. Make sure these match your silicone material. For smaller jobs, a smaller tabletop model might be enough. If you’re churning out lots of parts, you’ll likely need a bigger, automated machine. Also, see if it uses liquid feeding systems. This helps keep things moving fast. Chatting with a supplier like CASINDA can help you find the perfect machine.

Q: Are oil press machines safe for making silicone products?

A: Definitely, when you use them the right way! Today’s models have built-in safety. They include temperature controls and pressure monitors. These features stop problems before they start. Just make sure your crew knows how to run them properly. Also, stick to the maintenance schedule. This keeps everything in tip-top shape.